Few things are cooler than making your own homemade vinegar. If that isn’t the nerdiest foodie statement ever I don’t know what is, but it’s true.

Origins

What would a post about vinegar be without a little history?

Vinegar comes from two Latin words. Vinum meaning wine and acer meaning sour. That’s all it really was. Wine would be made from various grapes and other fruits and if exposed to air it would sour and turn to sour wine or vinegar.

Vinegar like many of our modern cultured foods was most likely an accident. A delicious and healthy accident.

Date (the fruit, not what you should be doing weekly with your spouse) vinegar is supposedly the oldest recorded vinegar, the Babylonian empire wrote about it some 3000 years ago.

Sciency Stuff

So vinegar really is one of the coolest products because it can only be made with two types of microorganisms present. A lot of our foods use the power of microorganisms to be produced: bacteria in yogurt and cheese, yeast in bread and alcohol, mold in cheese, some fungus we just eat and they aren’t so micro-y (not a word).

The two magic micros for vinegar production are yeast and acetobacter.

Now yeasts are actually classified as a fungus, they like to take sugars and simple carbohydrates and digest them. As a byproduct of their digestion, they produce ethanol (alcohol) and carbon dioxide (this is why yeast makes bread rise). This process of fermentation is anaerobic (done in the absence of oxygen).

When you make alcohol you are relying on yeast to take the sugars in your mixture and convert them to alcohol and carbon dioxide. That is why some wines are sparkling (the carbon dioxide is trapped) others are made with a one-way valve system that allows the carbon dioxide to escape.

Check out that carbon dioxide escaping.

When you are producing alcohols it is important to start with a known sugar concentration (known as Brix), because it is the sugar concentration (and yeast activity) that ultimately controls the alcohol concentration. For every 0.5 oz of sugar per quart of liquid, you can produce about 1% alcohol. That means your typical 80 proof Rum (40% alcohol) needed about 20 oz of sugar per quart or about 2.8 cups of sugar per quart.

However, I’m not a vintner, but am interested in the alcohol only to take it to the next step, vinegar. This is where acetobacter come in, these little buggers take the alcohols, that the yeast produced, and metabolize them into acetic acid (the acid in vinegar). These guys are aerobic (like Richard Simmons, don’t you feel like a pony), although some work has shown recently that acetobacter can survive anaerobic conditions, which is bad news for the dudes in Napa Valley, generally acetobacter need oxygen.

Thus in vinegar production, you produce alcohol with yeast without oxygen and acetic acid with acetobacter with oxygen. Complicated right?

The ratios I mentioned earlier are important even with the acetobacter. In order to be vinegar legally, there should be 4% acetic acid, to be safe 5%. The good news is acetobacter is very efficient at converting ethanol alcohol to acetobacter, up to 130% yields. Practically it would be between 100 and 120%.

That means your 80 proof bottle of rum would theoretically yield a whopping 48% acetic acid vinegar, which would be far far far too strong. So we dilute the alcohol before vinegar production to keep it in the 5-7% range (wine is about 11 or 12% alcohol).

Man, I love this stuff, it is just so cool how it works.

Fruit Scrap

You can make homemade vinegar in a myriad of ways, but today I’m going to talk about the simplest one, fruit scrap vinegar. (Imagine if I misplaced the s and it said fruits crap vinegar, no one would use that).

I love fruit scrap vinegar because I can make it out of so many things. To date, I’ve made Apple, Pear, Peach, Blackberry, Raspberry, and even Pumpkin vinegar (cause I’m awesome like that). The process is simple the results are cool and it is a great teaching tool for demonstrating fermentation principles to your little ones.

This kind of vinegar doesn’t rely on the natural sugars in the fruit but we add sugar and water to ensure that alcohol can be produced. Natural yeast in the air cause the fermentation to begin and often the environmental acetobacter (meaning I don’t know where they come from) will convert the alcohol to acetic acid. I typically add some acetobacter to ensure it happens and speed it up.

How To

You will need 4 things to make your vinegar.

First, fruit scraps. This is the apple cores and peels from applesauce, the peach peels from peach pie, whole berries, or a diced baked sweet pie pumpkin for pumpkin vinegar.

The second thing you need is a large non-metallic vessel. I like to use glass or earthenware, but plastic works well too. You will need a way to cover the vessel with a cloth. 1/2 gallon mason jars work great.

Thirdly, you need water and sugar. I mix 1 cup of sugar to one quart of water at the most. Under ideal circumstances that would give me 14% alcohol, but I know my circumstances at home will be less than ideal so it will most likely be substantially less. Don’t mix less than 1/2 a cup for really not sweet fruit as it can result is a super weak vinegar that is no good and unsafe.

Fourth you need time (not thyme). This is a fermentation process and it will take some time to produce, but it is well worth it.

Step one. Place all your fruit scraps in a suitable container (again not metal as it reacts with the acetic acid). I like to fill the container about two-thirds full with scraps, don’t pack them, just fill loosely.

Pour in the water/sugar mix, make sure the fruit is completely covered.

Cover the container with a cotton cloth (painters rags work great). The cloth serves three purposes: 1. It keeps fruit flies out of your vinegar 2. Allows the carbon dioxide escape when you are fermenting 3. It allows oxygen in when you are converting alcohol to acetic acid.

Secure the cloth with twine or bungee.

Place mixture in a warm area of the house. Furnace room or utility closets work great.

Check daily, push the fruit down under the liquid as needed.

This is apple vinegar, there is blackberry behind it.

You will start to see bubbles and foam forming in the liquid, this is the carbon dioxide trying to escape. After about a week to a week and a half, you will smell the alcohol.

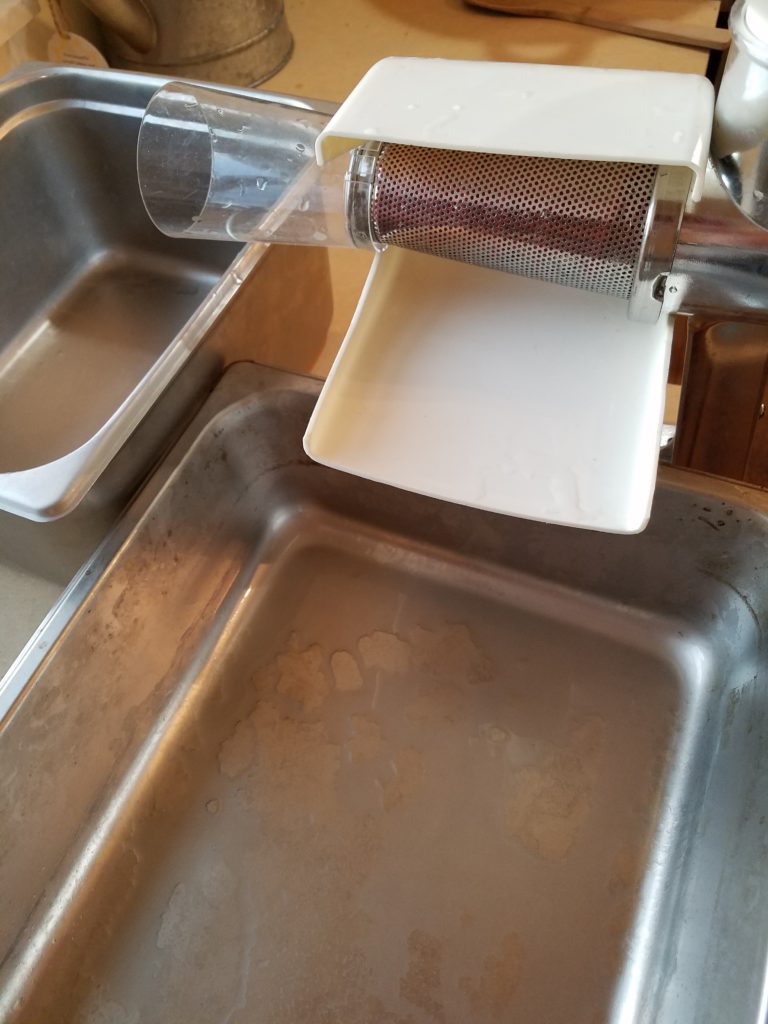

Drain all the liquid off and discard the solids. I feed my solids to my chickens, they love it, I guess they are drunken chickens.

Place the liquid back in the jar. I add a couple of tablespoons of Braggs vinegar (because it has live acetobacter) here. You don’t have to add the vinegar, but sometimes there isn’t enough environmentally and I don’t like to go through all the work for it to fail.

Re-cover the container with the cloth.

Store in a warm room and stir a couple of times a week to get more oxygen in the vinegar. You will begin to see a layer of goo form on top. This is known as the mother of vinegar and is where the acetobacter is heavily concentrated. This may take about one to two more weeks.

Mother forming on top.

The vinegar is ready when you can smell the vinegar and the mother is really prevalent. You can put it in mason jars with tight lids to keep it for about a year.

There you have it, your own wonderful vinegar that you can make right at home. The beauty of this is you can let your creativity really run with this and make almost any fruit you want and even combine flavor or add additives (I had cinnamon sticks in my apple vinegar). Enjoy.

Comments